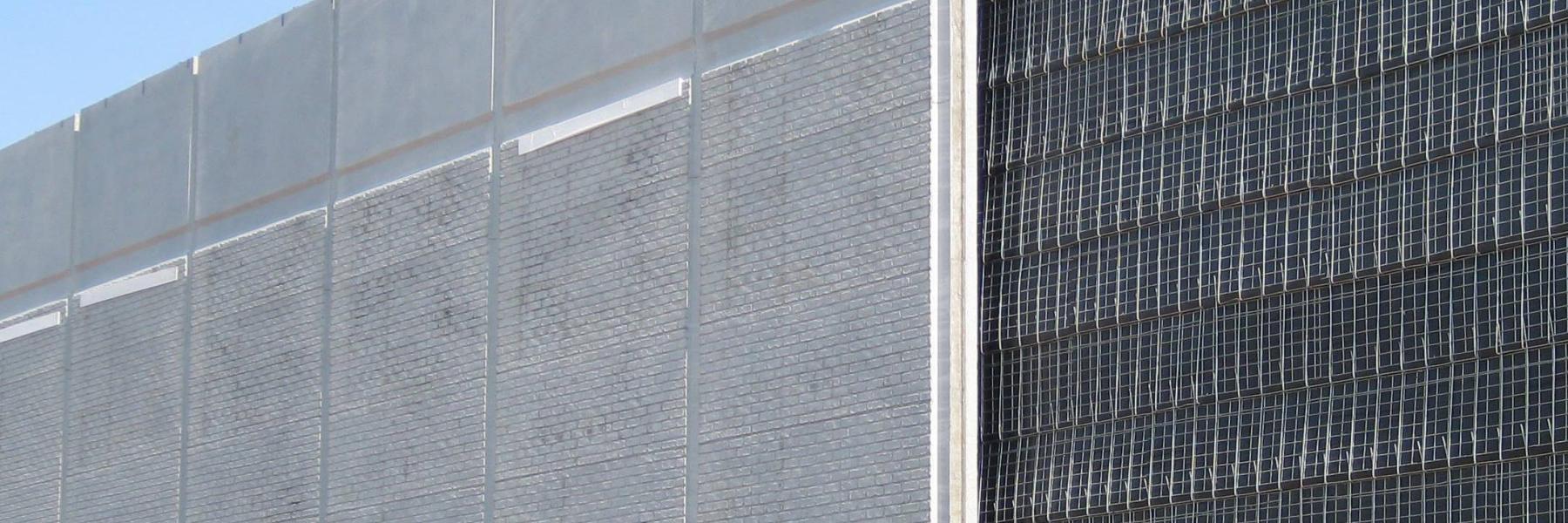

Similar in concept and construction to the Welded Wire Wall, but with the addition of concrete panels at the wall face, offering all the advantages of two-stage construction.

The ERS system can be utilized to accommodate poor foundations that cause differential settlement within the wall, or simply for aesthetics when a certain full-height architectural pattern fascia is required.

Cast-in-Place (CIP) Concrete Panels

Stage 1: Form anchors are installed in a specific size and pattern as the wall is erected, to accommodate the desired facing form system and pour rates.

Stage 2: Upon wall completion and any required settlement period, the reinforcing steel and forming system are erected utilizing the previously installed form anchors, then a 6”-8” thick fascia is poured and stripped.

Sample Panel Anchors

Precast Full-Height Concrete Panels

Stage 1: Typically two connection brackets are provided at the top of each panel and the associated panel anchor placed in appropriate locations during wall installation.

Stage 2: Upon wall completion and any required settlement period, the precast panels are lifted into place and secured to the wire-faced MSE wall.

Sample Panel Anchors

Other Finishes

The E.R.S. can also just be treated with a blown mortar (shotcrete) finish, sculpted shotcrete, or natural rock facing.