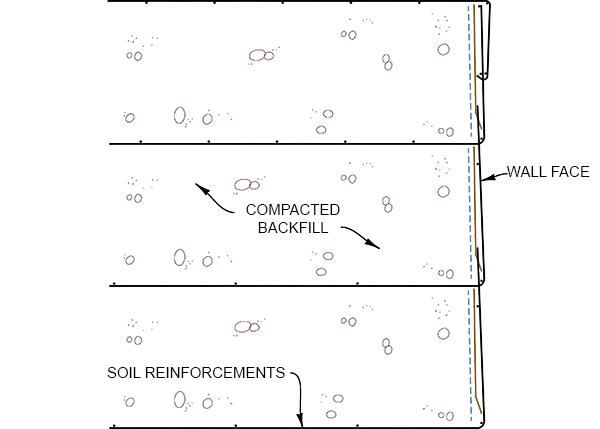

Hilfiker’s Welded Wire Wall is an inextensible, all-steel Mechanically Stabilized Earth (MSE) retaining wall system made up of ready-to-install L-shaped welded wire mesh mats placed within layers of compacted soil. The welded wire mats reinforce the soil, providing the tensile strength to make the compacted soil into a stable structure.

Unlike other MSE systems, the facing and soil reinforcement component is a single L-shaped unit, eliminating any need for a connection between the two and simplifying wall installation. Other advantages include:

- ease of wall alignment and mat placement

- design adaptability to various site conditions

- project and site-specific manufactured materials

- simple field cutting modifications for obstructions

- lightweight components requiring minimal labor and equipment, and

- quick back-filling and wall erection.

Being first patented in 1976 by William K. Hilfiker (Bill, Sr.), the Welded Wire Wall has many decades of substantiated wall performance history.

Compressible Facing

Hilfiker Retaining Walls developed the compressible facing for the Welded Wire Wall in the mid-90’s, which mitigates post-construction bulging in the layers and facing deformation. This feature allows our walls to accommodate differential settlement, and also has labor and equipment advantages during construction. Some agencies have since adopted and required this feature in their project specifications for wire-faced walls.

Versatility

The Welded Wire Wall can be designed for a variety of applications, site conditions, and desired aesthetics.

The wall face can be:

- battered

- vertical

- tiered / stepped

- cantilever

- non-galvanized wire, for an aged, rusted look, or

- galvanized for a polished, metallic look

- exposed wire

- vegetated

- covered with a concrete panels, shotcrete, wood, or other facing

While its primary function is a retaining wall structure, some alternate applications include:

- storm damage repair

- true bridge abutments

- embankment stabilization

- storage facilities

- erosion control

- mine facilities – crushers and truck dumps

- support for haul roads or buildings

- temporary structures for construction staging

- rock fall protection

Wall height and loading isn’t a problem, given the proper design parameters and backfill soil properties. Hilfiker’s tallest wall design to date is over 180 feet! And for our mining applications, loading has been over 600 tons!